Release time:2024-12-04

1. Mold blank preparation. Most die blanks are metal, taking destruction processing as an example. The raw materials for forging are generally bars, plates and pipes. Operators mainly choose according to the specific shape and geometric size of the blank. For sheet blanks, ordinary blanking or precision blanking can be used. If it is necessary to forge the annular parts, the pipe can also be used to cut the blank.

2. Rough machining of parts. Rough machining of parts we take iron cutting as an example. As long as the outline and island of the part are given, the machining path can be generated. Moreover, the arc can be automatically added at the sharp corners of the track to ensure the smoothness of the track and meet the requirements of high-speed machining. It is mainly used for milling planes and grooves. Multiple contours and islands can be selected for processing.

3. Semi finishing. The semi finishing stage is to complete the processing of the secondary surface and prepare for the finishing of the main surface.

4. Heat treatment. Heat treatment is a comprehensive process in which materials are heated, insulated and cooled in a certain medium, and their properties are controlled by changing the surface or internal structure of materials. The heat treatment process generally includes three processes: heating, insulation and cooling. Sometimes only the two processes of heating and cooling are connected with each other and cannot be interrupted.

5. Finish machining. The machining allowance of finish machining is less than that of rough machining. Select appropriate props for cutting, control the walking speed and rotation speed of props, and pay attention to the size and gloss appearance of materials.

6. Cavity surface treatment. Different surface treatment methods of the mold can change the chemical composition, structure and performance of the mold surface, and greatly improve and enhance the surface performance of the mold. Such as hardness, wear resistance, friction performance, demoulding performance, heat insulation performance, high temperature resistance and corrosion resistance.

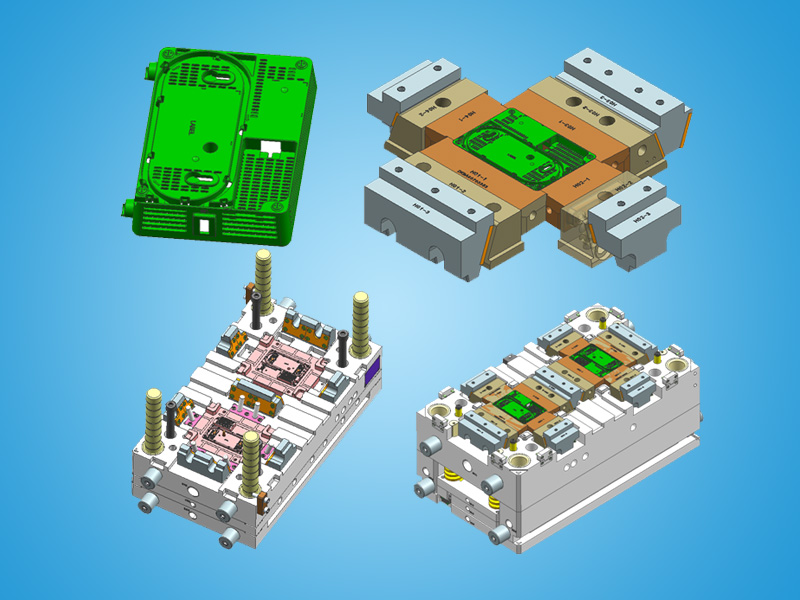

7. Mold assembly. According to certain technical requirements, the process of assembling parts into components, and then assembling into parts or even the whole machine. There are two forms of assembly, one is fixed assembly, the other is mobile assembly. Different mass production uses different assembly methods.